APS stands for ‘Advanced Planning and Scheduling’ – The core tasks of Opcenter APS (formerly Preactor APS) are detailed planning and capacity planning for all production resources. Opcenter APS generates a production plan in minutes that takes into account all rules and restrictions and defines a start and end date for each operation within the planning horizon. The plan can be further optimised through manual intervention and scenario analysis. This allows you to optimally control throughput times, working capital or set-up times, for example. As part of capacity planning, the production planning software ensures that sufficient capacity is available at the resource level. Unlike in the past, checks are no longer made against anonymous hour pools, but specifically against machines.

Within just a few days of training, you will be able to use Opcenter APS (formerly Preactor APS). The full functionality of the APS tool is available. Opcenter also allows you to quickly and easily make menu-based and field-based adjustments to individual values, such as parameter adjustments for process and delivery times, machine cycles, personnel capacities, etc. Opcenter automatically creates a production plan that takes all specified rules and restrictions into account. The plan is always transparent to you because the planning rules are developed jointly in the project. You have the option of manually overriding the result using drag & drop. In addition, automated warning/lock messages can also be created. The production planning programme can plan any period of time, which can also be adjusted at any time.

With Opcenter APS (formerly Preactor APS), your planner has all influencing factors under control at the same time:

- Delivery dates and priorities of customer orders

- Material availability: raw materials, semi-finished goods, extended workbench

- All resources with individual calendars: machines, tools, containers, means of transport, testing equipment, manual workstations, etc.

- Setup optimisation with multiple setup tables

- Personnel with consideration of qualifications

- Scheduling relationships between assemblies and multi-level sub-assemblies (multi-level bill of materials)

- Specific rules for production processes, such as minimum or maximum idle times

- Factors influencing productivity, such as setup matrices and dependent machine speeds

Opcenter is designed to work with other systems rather than replace them. It integrates seamlessly with ERP systems, financial software, spreadsheets, MES and production data collection systems.

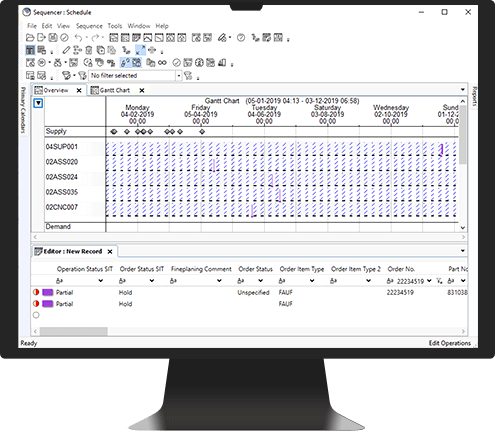

Opcenter APS creates a detailed production plan by distributing the work steps of orders across resources, taking into account all the rules necessary for creating a realistic detailed plan. An interactive drag-and-drop environment enables you to respond efficiently to unexpected changes in demand and capacity. This allows you to optimise output and on-time delivery even in difficult situations.

Opcenter is essentially an ‘out-of-the-box’ system that allows for simple configuration in a very short time. Implementation projects usually take between two and six months. The duration of implementation depends on various factors:

- Complexity and scope

- Machine resources

- Human resources

- Tools

- Allocation rules

- Manufacturing processes and dependencies

- Routing

- System architecture

- Single-level

- Multi-level

- Customer requirements for the system

- Interfaces

In order to estimate the exact duration of a project, we are happy to offer analysis workshops on site so that we can draw up a detailed quote based on specific requirements. Alternatively, we can discuss the key data of your project in a one-day meeting to arrive at an initial rough estimate.

Want to know if Opcenter meets your needs? Just download our trial version.

Every industry has its own specific characteristics and challenges. We offer Opcenter industry packages to help your company reap the benefits of the production planning programme faster and more cost-effectively.

Our Opcenter industry solutions were developed based on the Opcenter standard software and include numerous industry-specific functions. These help you automate your planning processes in the right places. This saves you time when planning and allows you to leverage the optimisation potential of planning algorithms.

Customers who work with us achieve their desired ROI with Opcenter APS (formerly Preactor APS) production planning software after just a few weeks or months.

With a team of 35 Opcenter APS experts, we offer you a competence centre for the implementation of production planning software.

What We Offer You

Free Analysis

We analyse your existing software landscape and work with you to determine whether Opcenter APS (formerly Preactor APS) is the right solution for you.

Get some no-strings advice from our experts and get a head start on the competition with our production planning tool.

Christian Stiefsohn

Your production deserves better. Plan correctly now with the production planning programme, with us as specialists at your side. In our free webinar, we will show you trends in production planning, present the state-of-the-art planning tool Opcenter APS (formerly Preactor APS) and clarify whether the application of the software tool is suitable for your individual needs.

Opcenter APS Advantages

Reduce your manual planning effort by up to 65%.

Why Should You Work With Us?

Discover Our Production Planning Software Solutions

With an industry solution from MCP, you enjoy many advantages: Your project costs are significantly lower than if you were to start with the standard Opcenter APS (formerly Preactor APS) software alone. You can see a lot of your future planning solution before you decide on Opcenter APS (formerly Preactor APS). During implementation, we build on the industry solution and adapt it to your needs. You can expand the solution where you can gain a competitive advantage for your company.

MCP implements exactly what you need. Opcenter APS (formerly Preactor APS) is extremely flexible to parameterise and, with an API, also offers the option of extending the standard software with customer-specific source code. This may be necessary for smaller logical requirements, but we can also solve difficult planning problems using customer-specific algorithms. This opens up unlimited possibilities for optimisation. Our customers with a customised Opcenter APS (formerly Preactor APS) solution also benefit from everything we have to offer as the world’s largest implementation partner for Opcenter APS (formerly Preactor APS), including modules, add-ons and ready-made configurations.

In our customised webinar, we will be happy to advise you free of charge on our Preactor customised solution for your company.

Start your digitalisation journey today.

We will help you optimise your production with the help of software

We will examine your planning problem with you and determine how you can obtain a functional and affordable tool: with standard software, custom development, or a combination of both.