Get some no-strings advice from our experts and get a head start on the competition with our production planning tool.

In our no-obligation webinar, we will show you trends in production planning, present the state-of-the-art Preactor planning tool and clarify whether the application of the software tool is suitable for your individual needs.

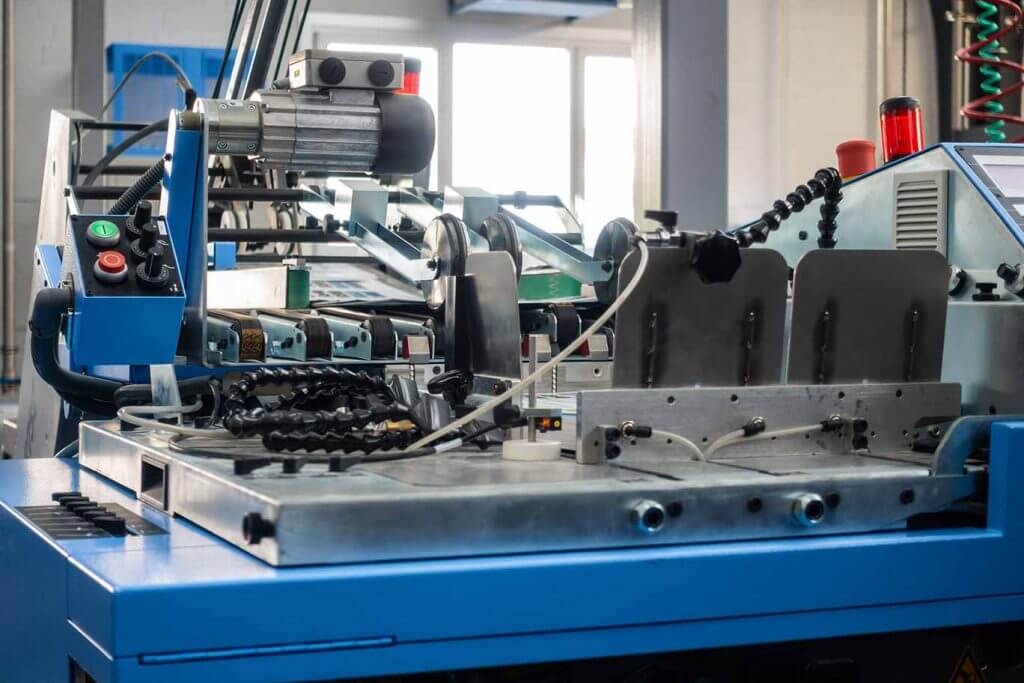

MCP offers you best practices and proven configurations for production planning from the laminating machine or printing press to gluing.

How to Achieve Your ROI With Opcenter APS (Formerly Preactor APS)

Up to

More Productivity

Up to

Lower Quality Costs

Up to

Less Inventory

Up to

Fewer Delays

Up to

Better Customer Service: Faster and More Reliable Than The Competition

Need an Example? How Can You Reduce Quality Costs Through Better Production Planning in Your Print Shop?

Get some no-strings advice from our experts and get a head start on the competition with our production planning tool.

One of the biggest problems with inadequate production planning in printing companies is the lack of transparency regarding capacity utilisation. This leads management to tend to build up more printing than is economically viable. Planners are unable to convince them that it would be better to reject a deadline request. The order is accepted with the motto ‘We have to do it!’. During the execution of the order, a few ‘unforeseeable’ problems arise and the workflow becomes increasingly hectic. As a result, the printers work a little faster than they should, and some of the commission for the pharmaceutical customer has blurred printing. Now the order has to be sorted out and re-produced, and it is finished significantly late. Anyone who has a post-calculation will see the order as a margin killer. And a follow-up order has too little cardboard because a pallet was diverted for re-production. Anyone familiar with the industry knows what happens next.

All this happens much less frequently when forecasting capabilities in planning are significantly better and everyone in the company can understand the forecast at a glance. MCP consultants can also help you with this change process.

Master Your Daily Business Faster and Better With MCP’s Production Planning Solution for Printing Companies

Christian Stiefsohn

In the packaging industry, manufacturers often face much larger companies on both the supplier and customer side. With print production planning from MCP, you can strengthen your position with reliable and traceable facts.

Get some no-strings advice from our experts and get a head start on the competition with our production planning tool.

You Can Eliminate These Tedious Processes With the Production Planning Solution for Printing Companies

Get some no-strings advice from our experts and get a head start on the competition with our production planning tool.

MCP’s consulting services help you overcome your established planning processes and their idiosyncrasies. Many print shops are still too much like craft businesses, relying on the experience and dedication of their employees. We help you develop the potential of planning tools and the experience of your planners to create a stronger planning process. The company benefits from optimised logistics and production thanks to better key performance indicators, while planners benefit from less personal stress and easier holiday cover.

Solving Customer Problems Through Flexibility

With the Production Planning Solution for Printing Companies By MCP

You solve the scheduling problems of customers who deliver their layouts/designs/approvals too late: You plan with a strong focus on short production lead times and thus make up for lost time. At the same time, you can see exactly how tight the buffers between work steps are, even with overlapping production, without any additional effort.

You also deliver orders on time, even those that the customer places with you late: thanks to the option of sequencing with weighted target criteria, you can strike a healthy balance between adherence to deadlines and setup optimisation. Let the ‘power of scheduling’ of Opcenter APS (formerly Preactor APS) work for you.

Short-term quantity changes: Change the quantity of the affected order during the phone call (what-if scenario) and see immediately whether this will jeopardise or even delay other orders. You and your customer save time and hassle with emails containing endless questions.

Overview: You can inform your customers at any time about the planned completion date for each individual order. It is up to you to decide how much buffer time to add.

What Changes for Planners?

However, due to the necessary flexibility, product diversity and numerous changes and disruptions in the primary packaging segment, the experience of planners remains just as important as it was before digitalisation. The eye of the planner and their manual intervention in special situations cannot be replaced by algorithms. However, algorithms help planners to optimise and save a lot of time. Planners can use the free time for optimisation:

Get some no-strings advice from our experts and get a head start on the competition with our production planning tool.