Let our experts advise you without obligation and secure your competitive advantage with the Demand Planning Tool.

In our non-binding potential discussion, we will show you trends in production and supply chain planning, look at your processes and discuss the sensible use of software-supported planning.

Developed for breweries and beverage producers who want to better plan for volatile demand and reduce costs at the same time.

Covid-19 and the structural change in the beer market have highlighted the limits of traditional planning processes:

- Lockdowns & catering closures → Demand collapses, sales shift to retail.

- Container size changes & promotions → Production planning reaches its limits when demand shifts at short notice.

- Falling beer sales → At the same time, pressure increases due to promotions and special offers.

- The result: inaccurate sales forecasts, excess stock, production downtime and unnecessary costs.

With the Gartner “Magic Quadrant” award-winning supply chain planning software Sunstice (formerly FuturMaster), breweries and beverage producers achieve

- +10-15% more accurate sales forecasts → less stock-outs & overproduction

- Optimised inventories → up to 7% less finished goods inventory and lower storage costs

- Shorter response times → flexible adaptation to market trends, promotions and external shocks

More than 600 companies worldwide rely on Sunstice

Both established global players and fast-growing newcomers are strengthening their market position:

+10–15% Forecast Accuracy = –25% Cost-to-Serve

The Solution: Sunstice Demand Planning

- AI-supported demand planning: Sunstice combines statistical methods with machine learning and external factors (e.g. weather data such as barbecue season, events, promotions) for highly accurate forecasts.

- More accuracy, less risk: A 10-15% increase in forecast accuracy reduces the cost-to-serve by up to 25%.

- Promotion optimisation: With a separate module for Promotion Planning & Management, breweries can immediately see which promotions really increase sales – and avoid expensive bad investments.

- Example KPI: A report on demand planning can be created in minutes instead of days, freeing up planners for value-adding analyses.

The Solution: Sunstice Supply Planning

- Optimisation instead of gut feeling: traditional tools reach their limits in today’s complex world. Sunstice uses mathematical optimisation to efficiently manage production, procurement and warehousing.

- Cost reduction through optimisation: Companies achieve a 7% reduction in stock levels and a 2% reduction in transport costs through global optimisation.

- React quickly, remain flexible: scenarios can be calculated in seconds – instead of rigid planning logic, there is dynamic control in real time.

- From cost block to competitive advantage: With FuturMaster, breweries transform complexity into transparent, controllable processes that directly strengthen competitiveness.

Christoph Hansal

Partner, Senior Expert Supply Chain

An integrated supply chain planning solution in just a few months: Thanks to our standardised approach for breweries and beverages, we integrate Sunstice into your system landscape as part of the project.

Let our experts advise you without obligation and secure your competitive advantage with the Demand Planning Tool.

In our non-binding potential discussion, we will show you trends in production and supply chain planning, look at your processes and discuss the sensible use of software-supported planning.

“State-of-the-Art” Demand Planning Based on the Following Principles

Optimised Supply Chain Planning With Sunstice

Standardised Solution for Breweries and Beverages

MCP has developed a standardised solution for supply chain planning in the beverage industry with Sunstice in order to get started as quickly as possible and take advantage of the benefits of Sunstice. This consists of 4 components and can be put into operation within a few weeks:

Interfaces and system embedding

- Integration of the Sunstice solution into the existing IT landscape

- Interfaces for automated data exchange with existing systems

- Integration of the data flow based on the defined processes

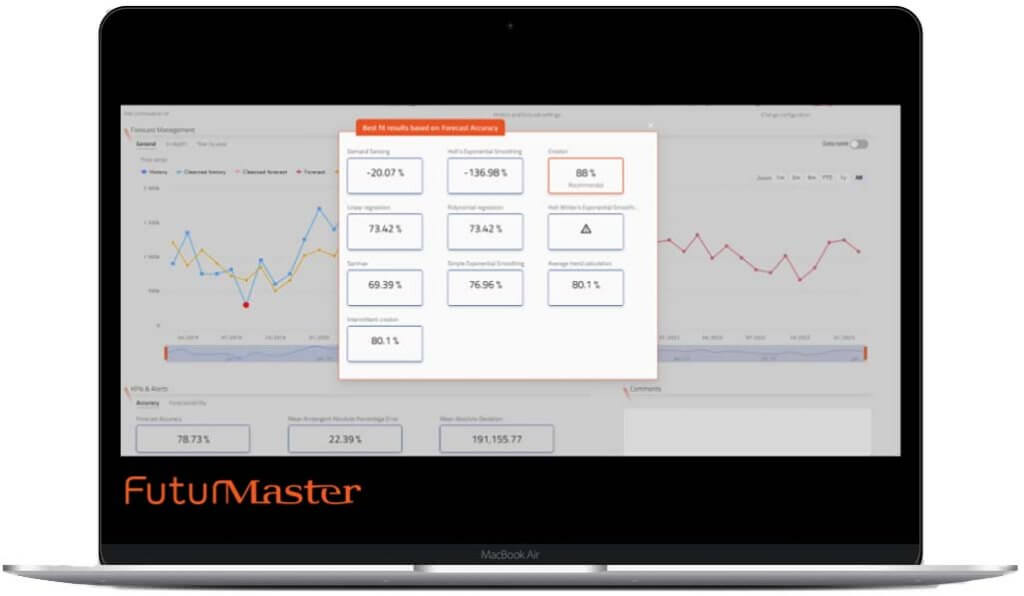

Demand Planning: Statistical forecasting & machine learning

- Statistical calculation and forecasting for the next 12 to 18 months

- Selection of “best fit” models

- Outliers, trends and recording of unusual events in the statistical model

- Manual and automatic processing of historical data based on the standard solution

Supply planning: mathematical optimisation & graphical analysis

- Modelling of the supply chain based on typical production and filling processes

- Use of standard screens to analyse and evaluate the plan

- Supply Network Visualisation: Graphical processing and problem analysis of the supply chain material flow

Demand Planning: Demand Enrichment & Promotion Planning

- Manual editing of the statistical forecast (“Forecast-Value-Add”)

- Intelligent analyser functions for rapid processing

- Recording of promotional measures

Supply planning: step-by-step optimisation of the plan

- Consideration of all restrictions and constraints

- Fully automated optimisation and decision-making

- Visualisation of all relevant material flow

Reporting & KPIs

- Management cockpit

- Process control cockpit

- Alerting and evaluation option

- Attractive analyses – expandable at any time

Success Story: Supply Chain Planning at Heineken

Watch the video to find out how Heineken successfully manages its supply chain with Sunstice.

Heineken, the second largest brewery in the world, has been using Sunstice (formerly FuturMaster) for years to optimise its entire supply chain. Today, the solution is used by almost 40 subsidiaries worldwide – with measurable success:

- Logistics costs sustainably reduced

- Inventories optimised → less capital tied up

- BBD losses reduced → less waste

- Sales growth thanks to more precise sales planning

Thanks to Sunstice, we were able to significantly increase our forecasting accuracy and at the same time make the supply chain more efficient and sustainable.

Your production planning and supply chain planning also deserves better! We will be happy to advise you in a non-binding potential check.

Register for a free potential check with just one click:

Our experts will be happy to give you a closer look at the supply chain planning solution for breweries and beverages using a demo.