Sales and Operations Planning

We work with you to implement the right processes and tools for integrated and efficient planning of your sales and operations processes: tailored to your requirements and the typical challenges of your industry.

Benefit from our many years of expertise and take advantage of a free consultation:

Your challenges in Sales and Operations Planning

Set up efficiently, the Sales and Operations Planning (S&OP) process is the central business management process in your company. By using the right tools and processes, all departments always have an up-to-date view of key information within the supply chain and can thus make the right decisions: Optimized management of promotions or new product launches are essential for business success in the FMCG (Fast Moving Consumer Goods), food or cosmetics industries, for example.

Creating transparency about inventory in a multi-level network, with a multitude of products, plants, suppliers and many planners is a key competitive advantage producing machines.

As an Algorithm Factory, we bring you additional exciting opportunities to not only manage but also excel in optimizing your supply chain using optimization algorithms, machine learning and artificial intelligence.

Across all industries, an integrated Sales and Operations Planning process provides your business with valuable information including updated data for Sales, Marketing, Finance and Operations. Despite the many benefits Sales and Operations Planning brings, a holistic process is still a thing of the future in many companies, as integration also brings many challenges.

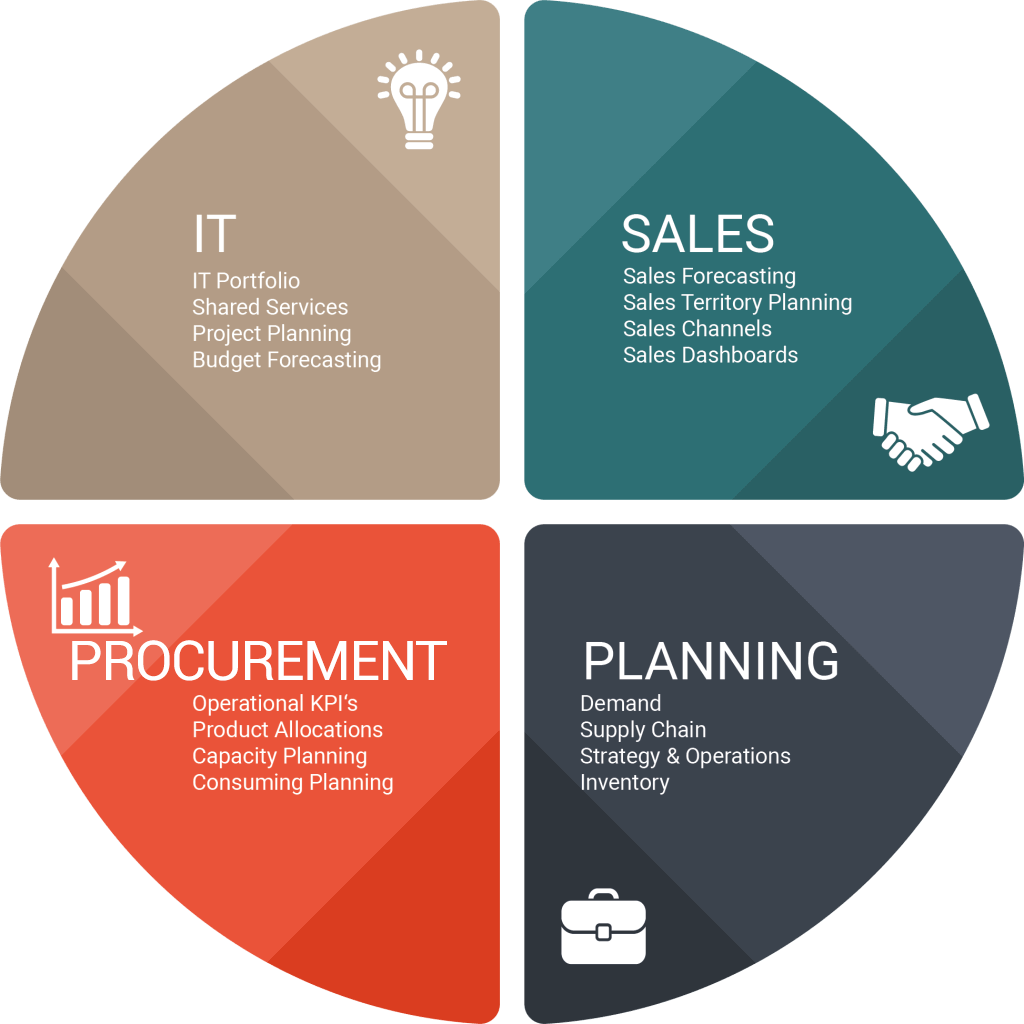

Which business units are involved in the Sales and Operations Planning process?

To coordinate a supply chain, many different departments in the company – procurement, production, sales, and IT – must be involved in the planning process.

The technological component plays a major role here. Modern IT – together with globalization – has made the development of complex supply chains possible in the first place. And it is indispensable when it comes to linking the individual players in the chain.

Your benefits from integrated sales and operations planning software

Optimal processes and tools help you achieve your business goals and quickly pay for themselves.

Our offer to you:

Free analysis

We analyze your existing processes and together we find out if the use of an integrated Sales and Operations Planning solution makes sense for you.

Let our experts advise you without obligation and secure your competitive advantage with our Supply Chain Planning Tool.

Christian Stiefsohn

Through our years of experience with the topic of production planning – both as consultants and as software implementation partners – we know the success factors for the effective digitization of Sales and Operations Planning. We have evaluated different S&OP vendors to help you choose the right tool for your challenges.

Your possibilities with S&OP software

Your main goals in the Sales and Operations Planning process:

- Reduce lead times for customers

- Synchronize material, capacity and allocation planning

- Improvement of the service level

- Optimization of inventory levels

- Reduction of inventory management costs

In order to coordinate a supply chain, many different departments within the company, such as procurement, production and sales, must be involved in the planning process. The technological component plays a major role in this process. Modern IT – together with globalization – has made the development of complex supply chains possible in the first place. And it is indispensable when it comes to linking the individual players in the chain. The following features of supply chain planning software can help you achieve your goals.

- Forecasting: Based on statistical methods and, if necessary, with the integration of machine learning, future demand for your product portfolio and markets is predicted

- Demand Planning: By adding specific estimates from your sales department, you adjust the result of the forecast to the actual expected demand.

- Supply Planning: The expected demand can be met by inventory, purchases or production at different locations. In Supply Planning, you allocate quantities to appropriate factories.

- Master Production Planning & Scheduling: In the course of “Master Production Planning and Scheduling”, you detail the production planning based on actual available capacities and further constraints.

- Inventory & Distribution Planning: Planning inventories in your warehouses and distribution centers ensures the right level of service on the one hand and the optimal inventory costs to achieve your goals on the other. This is how you prevent “out-of-stock” situations or non-saleable excess inventories.

- Strategic considerations and special processes: In addition to standard processes, you also have the development of new products, new markets, the planning of new plants or the relocation of different production sites and many other business cases under control

The phrase „You can’t manage what you can’t measure” is attributed to Austrian management author Peter Drucker. We help you to either embed the result of your supply chain decisions into your existing business intelligence solution or to use the reporting and evaluation options typically included in such solutions. Tailored to your individual goals.

Sales and Operations Planning with FuturMaster

More than 500 well-known customers with over 10,000 users trust FuturMaster as the integrated end-to-end supply chain solution (Sales & Operations Planning, Demand Management, Supply Planning) for the cosmetics industry and food industry: including L’Oréal, Weleda, Haribo, Heineken, Danone Waters, Lactalis and many more.

Sales and Operations Planning (S&OP) is an extended coordination function in which different areas in the company participate. Demand and supply must always be in balance, both in quantity and mix. S&OP deals with sales and production rates and outputs figures for inventories and backlogs accordingly. Unlike Master Planning, where supply and demand are balanced and it is planned which products are produced in which order, based on orders, S&OP also considers sales forecasts.

Typically, a large amount of information is already available in our customers’ ERP system. As with any software implementation, seamless integration into the system landscape is necessary. In addition to the standard solutions that exist within the various implementations, we also offer a connection via MCP Connector.

In addition to the technical inclusion, the process-related integration into your process landscape is, of course, of primary importance: We will be happy to advise you on the preparation of master data, the definition of persons responsible and the design of processes.

Just in Time (JIT) means the delivery of the right product in the right quantity in the right quality to the right place at the right time. Just in Sequence (JIS) means an additional consideration of the sequence.

Without the support of software, the execution of these processes is not possible today. We know the standard processes of the automotive industry and help you to implement them in your company. The processes and concepts of the automotive industry can also be transferred to other industries and thus a reduction of inventories while maintaining a high service level is feasible.

To coordinate a supply chain, many different departments in the company – procurement, production and sales, for example – have to be involved in the planning.

The technological component plays a major role here. Modern IT – together with globalization – has made the development of complex supply chains possible in the first place. And it is indispensable when it comes to connecting the individual players in the chain.

The task of supply chain planners is to reduce costs in the production process and by optimizing the process of supply and demand. In addition, efficiency is to be improved and margins increased. Often, the necessary transparency is lacking because manual planning tools are used. S&OP software gives all departments involved insight into updated plans. Synchronization is always possible, as the plans react immediately to changes.

Why should you work with us?